Test

Test

Robust 10" tablet as wireless remote control for all EVO orbital welding systems. The user interface of the EVO controller is mirrored 1:1, providing full access with all functions. As the data is sent over WLAN/LAN, there is no delay to the controls or display. The range complies with common WLAN/LAN standards and can therefore be easily amplified or extended. The tablet has an integrated 2D barcode or QR code scanner for user login and to access the welding programs. The tablet can be used as a mobile device and in the stationary docking station.

Technical data:

Tablet:

incl. software and QR code generator for PC for user login and accessing the welding programs

We have a comprehensive range of collets in stock for all OSK heads. 1 set per tube outer diameter = 4 half-shells. All collet Ø in stock can be found in the table on page 66. Other Ø and collets with a common contact surface are available as custom designs on request.

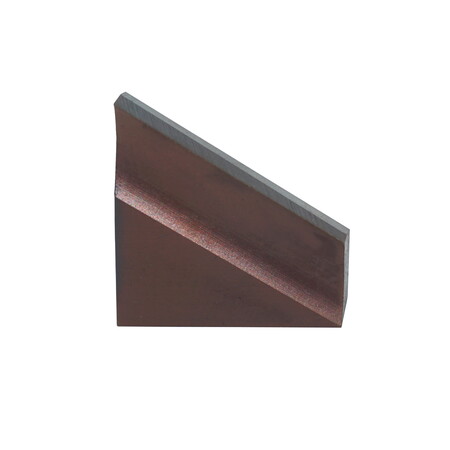

SuperArc: Precision-machined disposable tungsten electrodes for reproducible orbital welding. Cut your costs, because each new manual sharpening operation costs time and money. Standard quality WC 20 to DIN EN ISO 6848.

Finished dimensions for all ORBITEC weld heads as a function of the tube outer diameter.

for optimising the tempering colours in clean rooms available on request.

For welding where space is extremely tight

Required for the use using clamping blocks

incl. setting gauge for tube

(1 set = 4 collets) incl. setting gauge for tungsten

Tube to tube clamping block needed

The cylinder pressure regulator with manual connection reduces the cylinder pressure of compressed gases and gases dissolved under pressure of max. 200 bar (300 bar on request) to a pressure corresponding to the flowmeter. The desired flow rate in l/min can be constantly set on the flowmeter.

Important: This pressure regulator has a constant working pressure of 2.5 bar to protect the orbital system’s gas flow sensor.

Control range:

from OSK 53

The weld head size’s maximum tube size range is then reduced.

Lenght: 5 m / Size: 50 mm² / Voltage: up to 500 A

Handle and cable assemblies consisting of a handle with control element (start/stop button and status display), weld head interface, motor /gearbox unit and 8 m hose package. The OSK GW and SW handle and cable assemblies and weld heads are compatible with one another!

Paper rolls for integrated printer, pack of three (shelf life: 10 years)

The Gas Controller Box enables to control up to three gases during welding and regulate them through the EVO WP controllers. The welding, the purging, and an additional gas (e.g., for a trailing nozzle, for flooding a gas cover or a housing) can be monitored, regulated, completely documented, and stored in the EVO controllers. All welding and purging gases that are used for TIG welding are memorized in the controller menu.

Technical Data:

Package Includes:

Switchbox for welding with two welding heads. To increase productivity, the switch box can be used to weid alternately in conjunction with a controller from the EVO series with two weid heads. All welding tools can be used, i.e., enclosed weid and open frame weid heads, turn tables or tube-to-tube sheet weid heads, gas or water cooled, with or without wire feed or AVC. By pressing the start button on the weid head, the welding program suitable for the respective weid head will get loaded. The weid head that is not being used is locked and can get prepared for the next welding.

Technical Data:

Package includes:

Water cooling unit for use with the EVO 200 WP or LITE controller and TETRIX 200 in conjunction with water-cooled welding tools.

Package include:

Frost protection down to -10 °C (PU = 5 l canister)

The cylinder pressure regulator with manual connection reduces the cylinder pressure of compressed gases and gases dissolved under pressure of max. 200 bar (300 bar on request) to a pressure corresponding to the flowmeter. The desired flow rate in l/min can be constantly set on the flowmeter.

Important: This pressure regulator has a constant working pressure of 2.5 bar to protect the orbital system’s gas flow sensor.

Control range:

Pressure regulators with different connections and for use with other gas types / mixed or nickel-plated available on request.

(for RBK 60 S pneumatic connection)

incl. mounting bracket and inlet and outlet coupling (for RBK 60 S pneumatic connection). Pressure regulators with different connections and for other gas types or nickel-plated version available on request.

Lenght 3 m

Lenght: 5 m / Size: 35 mm² / Voltage: up to 530 A

Handle and cable assemblies consisting of a handle with control element (start/stop button and status display), weld head interface, motor / gearbox unit and 8 m hose package. The OSK G and S handle and cable assemblies and weld heads are compatible with one another!

for Tigtronic controllers

for Tigtronic controllers

Paper rolls for integrated printer, pack of 3

Colour ribbon cartridge for TIGTRONIC ORBITAL 4 integrated printer

gas-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

ED: AC: 105 A, DC: 220 A, 60% (10 min.)

Special lengths and versions with a higher ED available on request.

For all Tigtronic controllers for backing up, managing and editing the weld documentation (actual/target parameters) on a PC, in German and English

8-m cable remote control for all orbital welding controllers.

Package includes:

Technical Data: Orbifeed 15

Consisting of a handle with control element (start/stop button and status display), weld head interface, motor / gearbox unit and 8 m hose package.

from OSK 53

The weld head size’s maximum tube size range is then reduced.

GAS-shield collets are particularly narrow and have an aluminium base collet and a screw-on gas-shield collet made of heat-resistant GRP material. They are used to weld fittings, flanges and components with short welded hexagon nipples. In conjunction with offset or multi-position electrode holders, the weld can be completed very close to one side of the weld head. A collet set with a common contact surface is recommended for secure fixing. GAS-SHIELD collets are available for OSK 53 / 76 / 115 weld heads (the max. tube size range is limited).

GAS-SHIELD base collets and gas shields (1 set = 2 half-shells)

(adaptation by the customer)

(prefabricated with through hole)

Handle and cable assembly for OSK C and CS, consisting of a handle with control element (start/stop button and status display), weld head interface, motor / gearbox unit and 8 m hose package.

Advantage: While using this flange, you can also use the OSK C and CS weld heads with the OSK G or S handle and cable assembly.

with hose package, 8.5 m, gas-cooled, equipped with torch consumables and tungsten electrode Ø 1.6 mm

with hose package, 6 m, water-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

with hose package, 6 m, water-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

with hose package, 6 m, water-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

gas-cooled, for OSW 40 (Special tooling required)

Water-cooled version available on request.

gas-cooled, equipped with torch consumables and tungsten electrode Ø 2.4 mm

ED: AC: 105 A, DC:150 A, 60% (10 min.)

Special lengths and versions with a higher ED available on request.

Slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

incl. AVC motor with limit switching and 8 m connection cable, slide width 50 mm, torch travel 50 mm, lateral adjustment 30 mm incl. torch clamp OD 20 mm incl. mounting flange

(Special torch clamp OD 30 mm available on request)

incl. wire outlet nozzle and three nozzle tips for 0.8 / 1.0 / 1.2 mm

(3D adjustable via linear unit)

Package includes:

Technical Data: Orbifeed 5

Tube size range: 9.3 mm – 16.2 mm / 0.366" – 0.638"

Tube size range: 16 mm – 36.7 mm / 0.630" – 1.445"

Tube size range: 9.5 mm – 19.5 mm / 0.374" – 0.768"

Tube size range: 19.5 mm – 99.1 mm / 0.768" – 3.902"

Up to an ID of 30 mm, the spring sleeves are made of steel; in the case of larger diameters, the package also includes four stainless steel jaws.

Dimensions without holders installed:

1110 x 710 x 850 mm (L x W x H)

Weight: unloaded, approx. 70 kg

For attaching the tubes during tacking before welding / Surface-treated aluminium

For attaching the tubes during tacking before welding / Surface-treated aluminium

Scope of supply:

Scope of supply:

Includes inspection lamp and case

250 ml bottle

1 set per tube outer diameter = 2 half-shells. The collets of the OSK 38 welding head can also be used.

Offers a long service life and can be used to quickly and reliably machine unalloyed, low-alloyed and high-alloyed steels with high precision.

1 set per tube outer diameter = 2 half-shells.

The collets of the OSK 115 welding head can also be used.

Special HSS cutting steel for chamfering 30° and 37.5° available on request.

For 30° chamfering for Planfix 115

For U-joint preparation 15°/R3 for Planfix 115

OD 3 – 16 mm | 0.118 – 0.630″

Universal”, 10 – 54 mm | 0.394 – 2.126″ diameter

Roll 10 m | 393.701″, 115 mm | 4.528″ wide

Ø 150 mm | 5.905″ diameter

For connecting to TIGTRONIC ORBITAL and EVO, 3 m

For OXY 2 / EVO for connecting to TIGTRONIC BASIC 2 – 4 controllers

For OXY EVO for connecting to TIGTRONIC ORBITAL and EVO controllers

For OXY EVO for connecting to EVO and PC controllers, 2 m

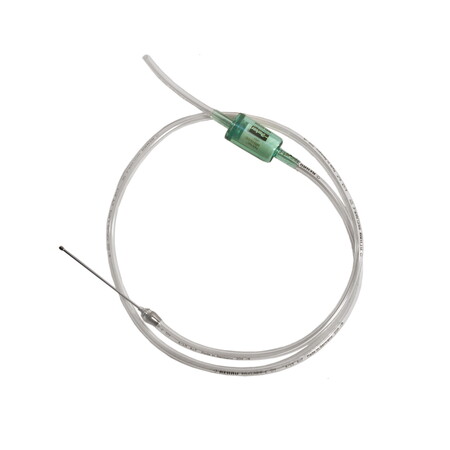

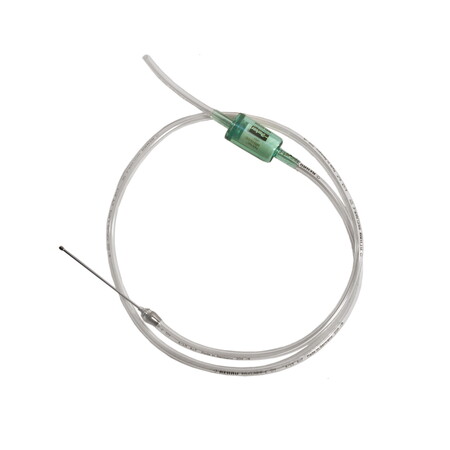

For OXY 2, 3, EVO, 3 m, with particle filter and stainless steel probe

1 m, with particle filter and stainless steel probe

(only mountable for large burners)

for glass gas nozzle

Other gas cups available on request.

OSW 80-275, TURN

Scope of supply:

1 burner cap

1 clamping sleeve

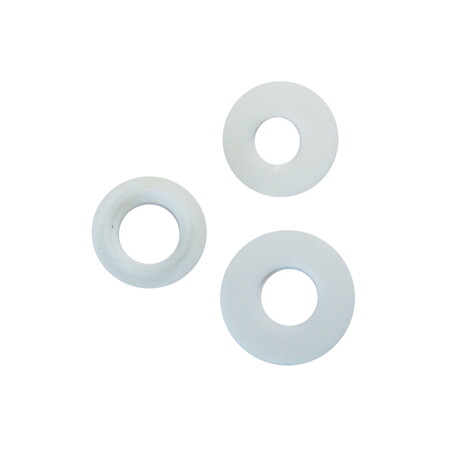

1 Teflon insulator

1 gas lens

1 gas lens holder

1 glass gas nozzle

Scope of supply:

Measuring connection for flexible purge dam to OXY

(from SC Profi diameter 57) on request

For an ID of 10.5 – 49 mm (0.413 – 1.929″) (10 x 2 bungs) in a case

For an ID of 47 – 107 mm (1.850 – 4.213″) (9 x 2 bungs) in a case

(Suitable for silicone bungs with 6-mm hole from an inner tube diameter of 15 mm)

6 x 15 x 48 mm

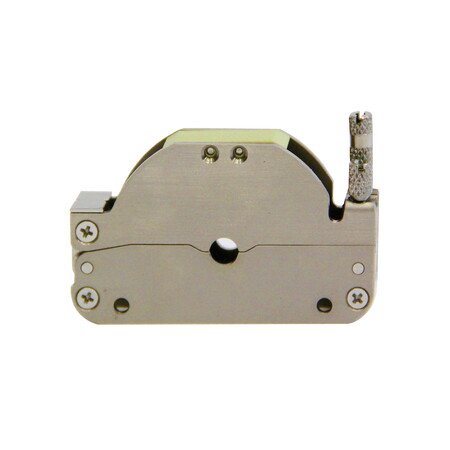

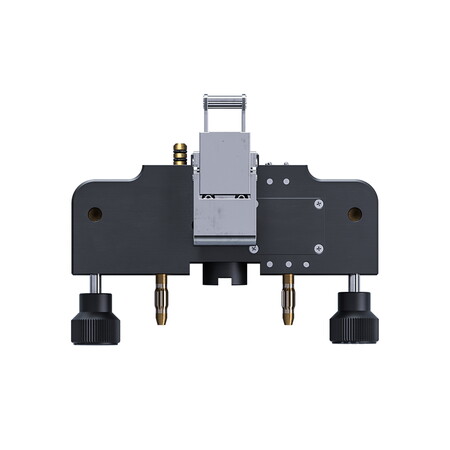

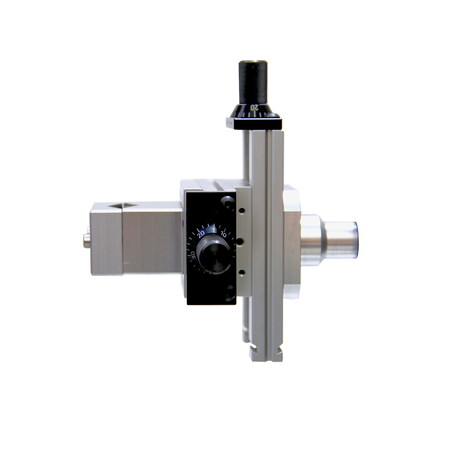

Portable tungsten grinders for precise and swift machining of tungsten electrodes for TIG orbital and manual welding.

Scope of supply:

Technical data S-TGS C // S-TGS CL

Can be used on both sides